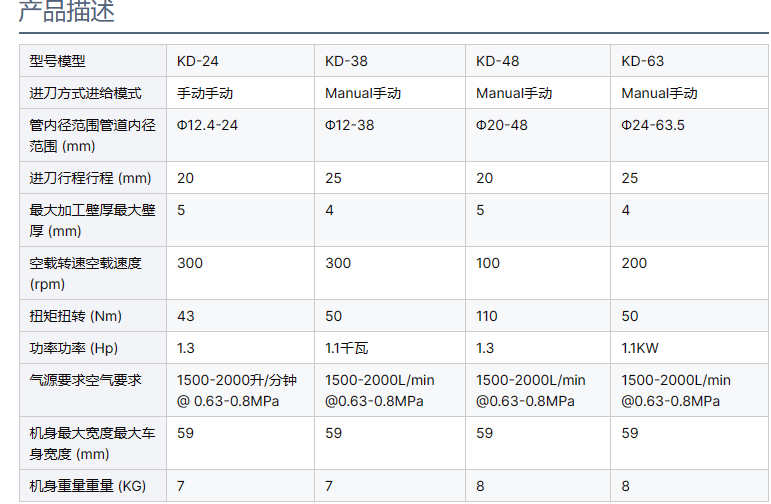

KDseries equipment is specially designed for the uneven nozzle in tube sheet welding, which affects the welding quality and product appearance. Its advantages are compact structure, light weight, simple operation and high processing efficiency. It is widely used for batch processing of end faces of various metal pipes, and for flat and groove processing of heat exchanger tube sheet cutting off excess length pipes.

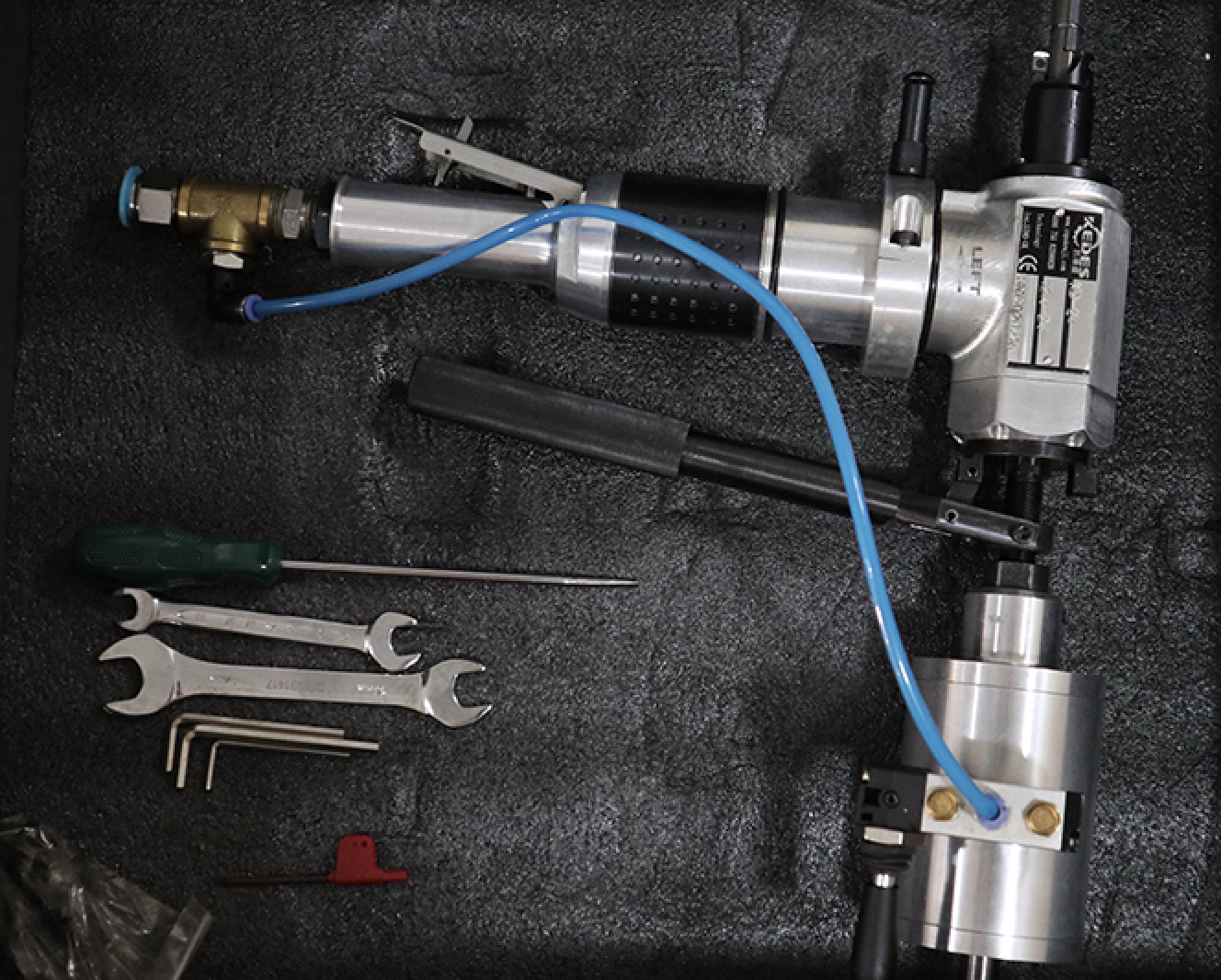

·complete cold working, do not change the pipe material;·pipe inner diameter, pneumatic fast positioning and tightening·Push rod type feed and retract, fast and convenient;

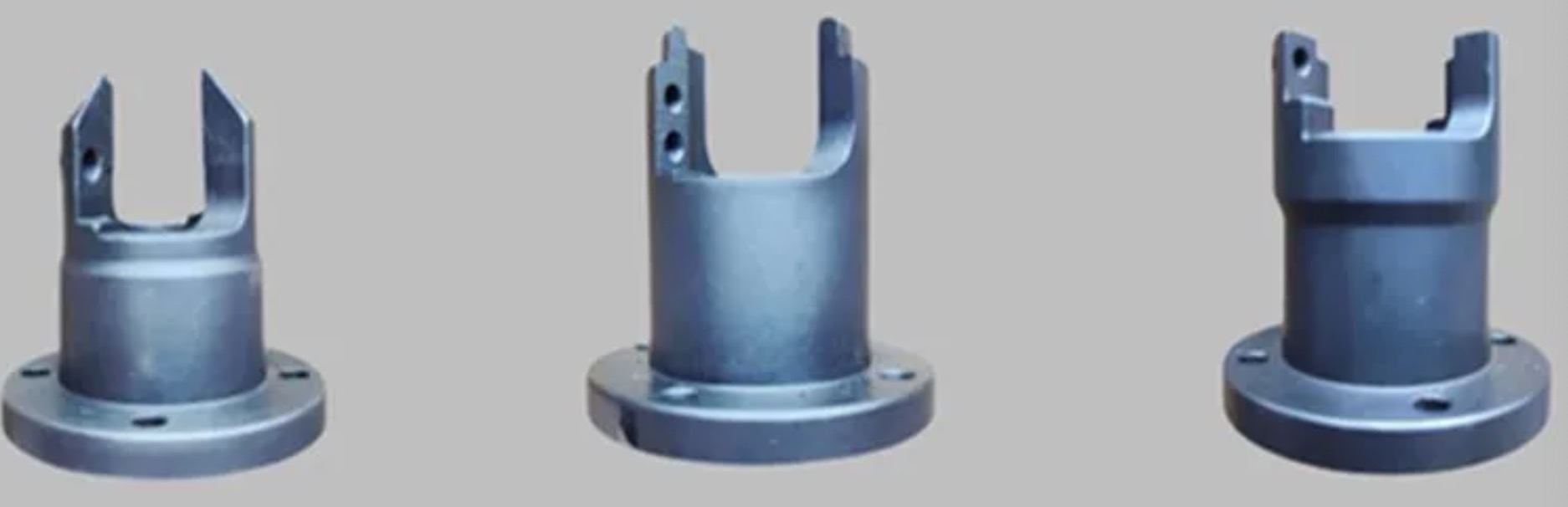

·can not only scrape off the excess length of the nozzle, but also quickly flare and groove can remove the weld.;

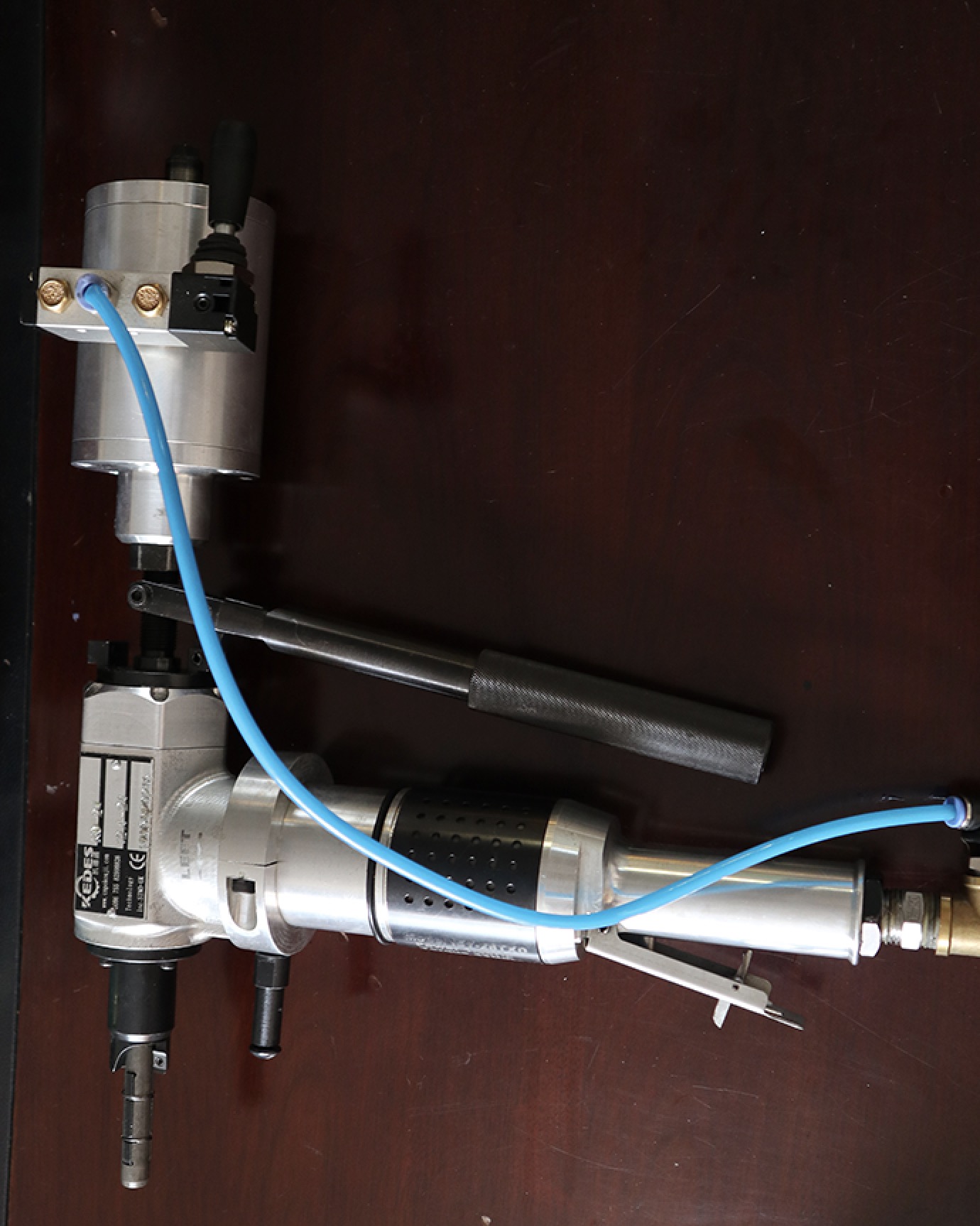

·Safe and comfortable ergonomic design, using the principle of balance to reduce the burden of operation;·The whole machine is small and light, easy to move, and can be used in various stations and conditions;

·Suitable for various grades of carbon steel, stainless steel, alloy steel and other metal pipe end processing.

Quick Chamfer

·In the manufacture of heat exchangers, the replacement of heat exchange tubes due to quality problems of heat exchange tubes·Due to weld quality problems, the weld needs to be removed and re-welded.·heat exchanger·Quick flatten nozzle

·heat exchanger, the nozzle is dense and the space of pipe bridge is small, which makes welding difficult and the protruding length of nozzle is uneven.